As this vlog video shows, you can still score some good Revere Ware finds at thrift stores.

Archive | 2018

Another way to repair a lid with a rusted on knob nut insert

We found this YouTube video on fixing a lid with a rusted on nut insert. I wonder if the guy tried simply unscrewing it, as we suggest in our repair guide for this situation.

It just goes to show, there is more than one way to approach a problem.

Revere Ware Tri-Ply cookware

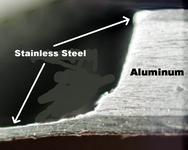

Revere Ware is most well known for its copper bottom cookware. An often overlooked variety is the aluminum core Tri-Ply cookware, which has an aluminum disk on the bottom of the piece sandwiched between an inner and outer stainless steel shell. An aluminum core is what most high-end cookware uses today to spread the heat out evenly.

The bottoms of these Tri-Ply pieces can be identified by the protruding disc on the bottom.

Here what our photo guide has to say about Tri-Ply cookware:

Kitchen technology changed in the mid 1980’s with the introduction of the smooth glass/ceramic cooktop surfaces. These surfaces used embedded thermostats requiring cookware with thick, cast metal bottoms (as opposed to the pressed steel or electroplated bottoms used by Revere Ware). In March of 1986, Revere responded with the Aluminum Disc Bottom Cookware, sometimes called “tri-ply” or “slab bottom” (identified internally as the 2000 line). It continued the classic Revere Ware styling of the earlier 1400 and 7000 lines, but used a stainless steel coated aluminum disc brazed to the bottom of each piece allowing for use on smooth cooktops (and giving it the heat dispersion capability needed for use on conventional cooktops. Initially, the discs were brazed and buffed in Korea, and the final product assembled at Clinton. Later the entire production process was moved to Clinton. The line was an immediate success, amounting to 20% Revere’s total cookware sales in 1986.

The aluminum disk is actually quite think and pretty effective at spreading the heat.

Because of the construction, these pieces are suitable for glass top stoves, as they are much more likely than the copper bottom variety to remain flat.

There is some danger though. We continue to receive more and more reports of the aluminum disk separating, dumping out molten aluminum.

At best, this can damage your cook-top, flooring, etc.. At worst, it cause injury. It isn’t clear if these failures occur due to extreme overheating, or just normal cooking. We’ve gotten enough reports that we can no longer recommend people use this line that has the disk.

There were other versions of Revere Ware deemed Tri-Ply as well, that contained a carbon steel core between two stainless steel layers. They were made to look like the tradition Revere Ware pans, sans the copper bottom. While the aluminum disk variety over these are likely better at spreading the heat, I wouldn’t consider them safe anymore. So if you want the Tri-Ply line, use the one with the embedded core. The carbon steel / embedded core variety will not have the round disc on the bottom.

Handle separation – repair or replace?

One of the most frequent questions we get asked is regarding handles where the butterfly wing-shaped piece of the handle spline has detached (either partially or fully) from the pot body. Here is an example.

We’ve never had a good answer to this question, so we set out to see what could be done.

Years ago, a brass spoon that my wife brought back from Thailand snapped along the stem when I tried to adjust the bend. At that time I was able to have it brazed back together, and the result looked pretty good. The stem was thick metal, and the brazing material was about the same color as the stem.

We posed this challenge to some experienced folks in an industrial metal-working shop, where lots of serious welding and brazing is done day in and day out.

Their first attempt was to weld the handle back on. As far as we can tell from the dots in the butterfly attachment (as can be seen above), the handles are spot welded on. This involves running a large amount of current from one side of the two pieces of metal to be joined, to the other. The internal resistance of the metal to electrical current causes the metal to heat up considerably, which fuses the metal pieces together.

However, it is often the case that when the spot welds on these type of handles fail, they create a hole in the pot body, so spot welding would not provide the best results in this case, as the holes would still be there.

Instead, they tried arc welding, with a consumable electrode. This is similar to spot welding, except that the electricity melts the consumable electrode, which leaves material behind to bind the two pieces together (and can fill holes).

What they found was that the metal of the pot was just too thin to perform any kind of welding on.

So instead, they turned to brazing. Brazing is a process that joins two pieces of metal by melting and flowing a filler metal. Think of soldering electronic components.

However, again because of the thin nature of the cookware metal, it wasn’t possible to heat up the metal quite enough to really flow the brazing metal enough to get a really clean seam. The result is a functional, but somewhat ugly sauce pan.

For us, this leads to an obvious conclusion; it just isn’t worth it to try and repair separated handles. The work will likely cost you far more than a used replacement piece from eBay (of which there are plenty), and the results are less than satisfactory.

If you do want to attempt this, find a local weld shop or machine shop and ask them if the can braze (not weld) the handle back on.

Thanks go out to Patricia for sending us her damaged pot for this repair attempt.

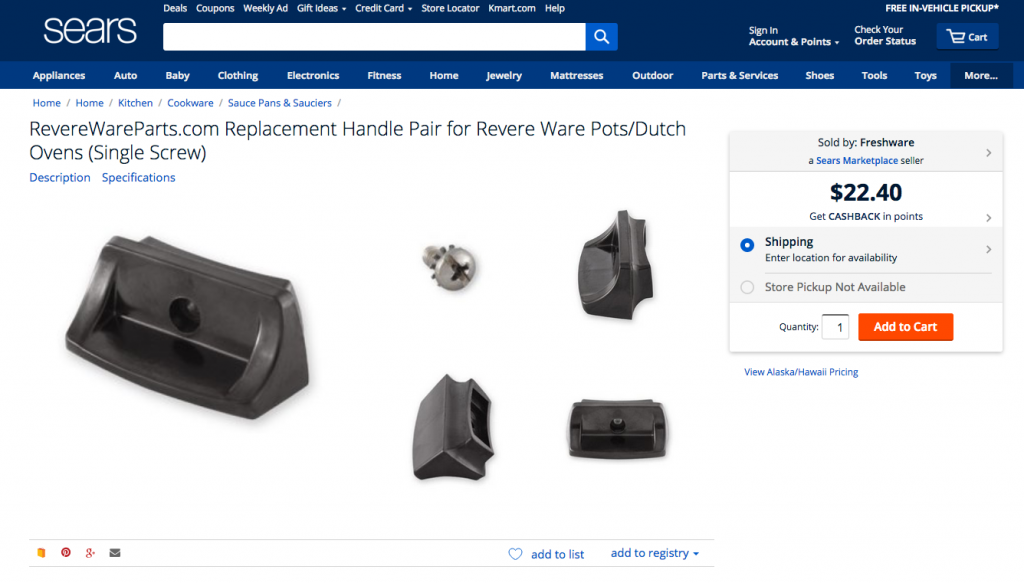

Someone is selling our parts on Sears.com now

Did anyone else know that Sears.com had a marketplace similar to Amazon.com where independent merchants can list and sell items? I certainly didn’t, until I came across this listing for our replacement pot handle there.

We’ve talked about this phenomenon before, where people are taking our Amazon.com listings and listing the parts on eBay and independent sites. What happens is that, when you place an order for one of the parts there, they simply activate a purchase on Amazon.com and have it shipped to you. But you are paying a premium over what you can buy it for on Amazon.com, as that is how these resellers are making money, and you are one link removed from us should there be an issue with the order; there is no guarantee that these resellers will field your call like we do, if there is a problem.

Improving dishwasher-worn Bakelite

Prior to our providing new Bakelite parts, the only option we knew of restoring faded dishwasher-worn Bakelite to its original look was a complicated process of repeated sanding process with finer and finer sandpaper offered by one restorer. They came out looking decent but it was a labor intensive (and expensive) process.

Availability of new handles made the a non-issue for many parts, but there are still some that we don’t produce, like the very early Revere Ware cookware handles. If fading (probably from repeated washing in a dish washer – see our test) is the issue, then we just came across something which might help.

We recently came across a blog post that talks about restoring Revere Ware pots and pans.

Their suggestion for Bakelite is:

What you need to do with these is actually use Mineral oil and rub it into the handles. Let them sit for a while (mine sat for a day) and then wipe off any access oil. This will bring them back to looking good.

From the pictures, there does seem to be quite an improvement:

Before:

After:

There does appear to be considerable improvement, although you can easily tell the difference in the after photo between the original Bakelite shine on one handle, and the rest of them with mineral oil restoration. For parts that simply aren’t available anymore, it can probably make a difference.

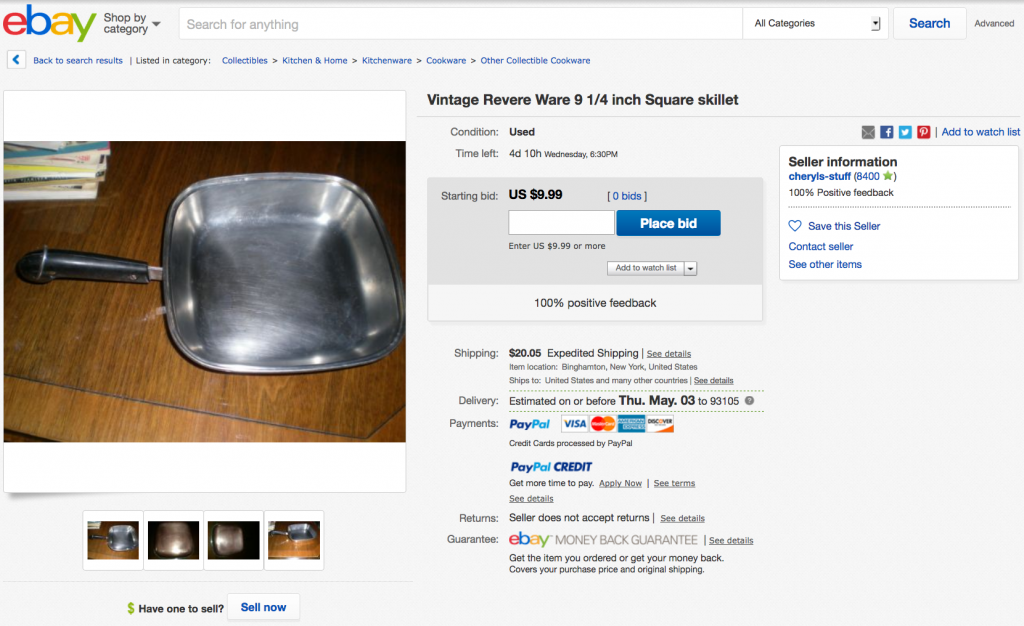

Revere Ware deal of the week?

This weeks deal is for a square skillet, which usually sell in the hundreds. This one, with out a lid, is listed for a starting bid of just $9.99.

Please don’t buy this

World Kitchen, which owns the Revere Ware brand along with a number of other iconic brands of yesteryear, no longer sells the classic copper bottom cookware. This is probably a good thing, as the quality of the cookware produced in the last decade was even worse than the rest of the post-1968 cheaper Revere Ware. We have oft heard stories of copper bottoms which appeared almost painted on, or simply fell off completely. I suspect they discontinued the copper bottom cookware because, after decades of poor quality, it had finally cheapened the Revere Ware name.

But you can still find new copper bottom cookware for sale. Consider this one on Amazon.com.

I was shocked to see the high price and the 4-star rating on this piece.

Do yourself a favor if you are looking to replace a sauce pan, or any other Revere Ware piece; buy a used one from eBay or your local thrift store. You can get one for less than half the price shipped and the vintage items (with the double circle process patent stamp) are readily available. They will last you another lifetime.

Rare does not equal valuable

You may guess from our blog posts that I spend a fair amount of time looking for things on eBay, and you would be correct. One of the most puzzling phenomenon is some sellers belief that rare equals valuable, despite evidence to the contrary. Consider this listing for an Apple Macintosh Picasso poster.

This seller has relisted this item continuously for at least 5 years, at a similar price. You think they would have gotten the message by now that no-one wants to pay that much for such a thing.

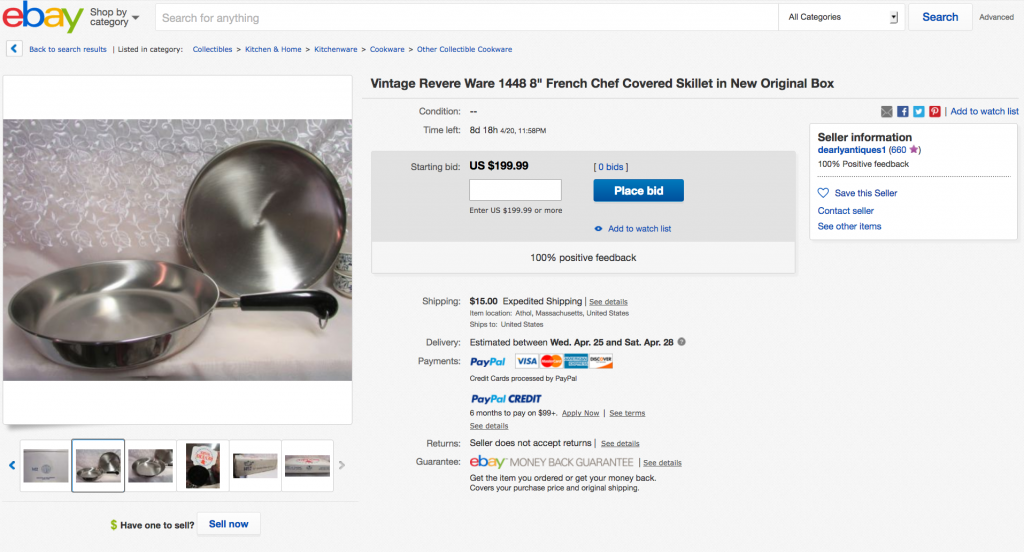

Along those lines comes a listing for a post-vintage era new skillet.

As most people familiar with just a little of the Revere Ware product history know, this particular skillet, while new, is far inferior to the ones made prior to 1968. A similar used one can be had for about $35-$40 on eBay, often cheaper, and probably far less at your local thrift store. And here is a brand new similar type sauce pan being offered for only $25.

It all points to wishful thinking. I would be shocked if this sold for such a price.

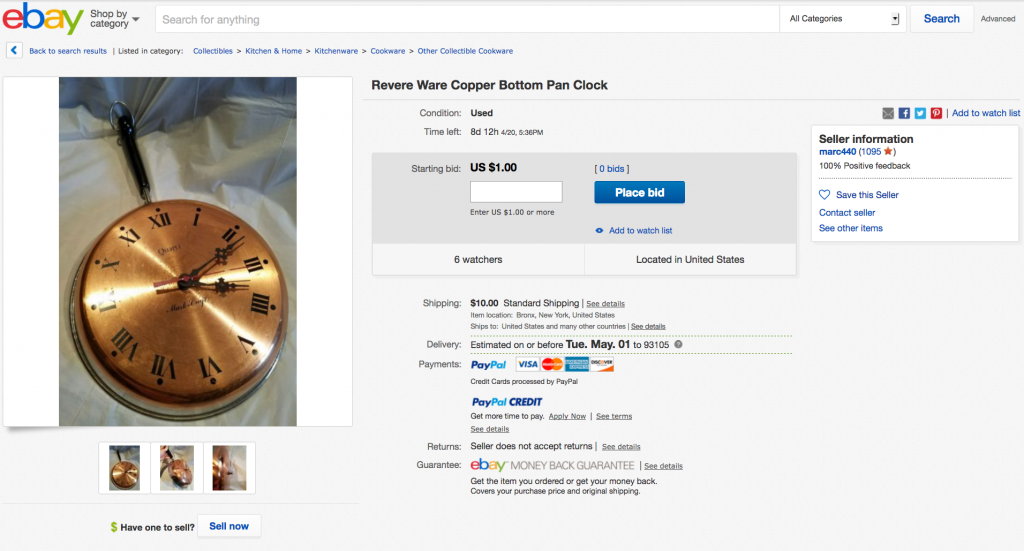

Revere Ware find of the week – Revere Ware pan clock

I’ll admit to having purchased one of these a number of years ago (auction link). I’m not sure of the history of these clocks, whether they were produced by Revere Ware or perhaps just one-off projects by individuals. This one certainly looks professionally made, with the painted on roman numerals.

Update May 2021

Francine tells us

The clock in your April 2018 post was made in Rome, NY by Mark Ogut. He was, I believe an engineer, who had his own business making clocks from unused Revere frying pans. He also make a tapestry of Rome, NY with its historical sires and Revere on it. If you’d like more information please feel free to contact me. His son is a dear lifelong friend.