Since our original attempt at 3D printing a trigger for the 3 quart kettle failed, we’ve been looking for the availability of a better material that might withstand the stove top heat.

In the original attempt, we used a material called Z-Glass. The properties of that material claimed a melting point of 437 F and a deflection temperature (where materials will start to bend) of 392 F. Since both of these were above the rated temperature of Bakelite of 350 F, we thought it might work. But it didn’t. After sitting on the stove for some time, the material got soft enough that when we tried to use the trigger, the end bent out of shape and stayed that way. Here is the original printed part and what it looked like after out attempt.

We tried again with an online 3D printing service called Shapeways. The material that seemed most appropriate is called Professional Plastic, and claims to be “heatproof” to 350 F.

Here is the new part compared with the Bakelite original.

As you would expect from 3D printing, the texture is much rougher than the original smooth finish. But the fit was good and it installed easily.

We tried this out on our 3 quart kettle by bringing it up to a whistle with a high a heat as our stove could give it without the flames licking up the sides.

As far as we can tell, the part seems to work. At whistling temperature, we were able to repeatedly pull the trigger without any noticeable deflection.

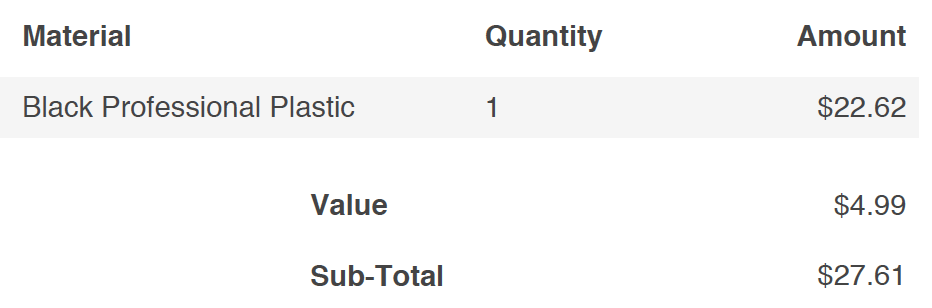

The downside is the cost.

However, when we went to reorder the part, the price was much cheaper, so the above price must have included one-time startup costs.

To make it easy to order these parts directly from Shapeways, we will be opening a shop there with this, and likely other designs of hard-to-find parts that don’t have enough volume to be made the traditional way. Stay tuned!