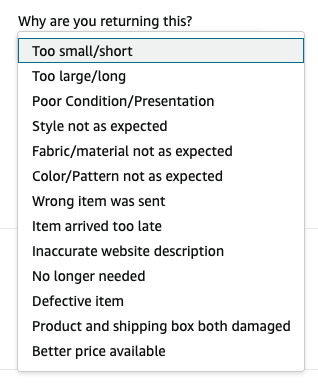

Amazon.com product returns have always been a black box. People return items and often choose a category for the return for which they don’t have to pay anything to return it.

Defective item and Inaccurate website description seem to be favorites, and provide us with almost no information as to what went wrong. We suspect that most returns are people simply not reading our product pages to make sure they get the right item, or buying things despite the warnings that it won’t work on anything but Revere Ware. (In contrast, we have very very few returns from items sold on our website, and people almost always ask for help if they have a problem. Even if they don’t, we often are able to avoid a return by providing suggestions along with the return info.)

Buried within the Amazon returns there are some people that have a problem they just need some help with. We recently started putting stickers on all of our Amazon.com products that list our Gmail address to contact for help, and we’ve gotten a few responses and have been able to help some folks.

As much as today’s consumers like expect things to just work, those of us familiar with vintage things, know that it sometimes takes some time and effort to fix things. Sometimes, you aren’t sure exactly what you have.

The part wasn’t defective. It just didn’t fit my pot. I assumed it’s a Revere Ware pot; it certainly looks like it. However, since the writing on the bottom of the pan is totally worn off, I could have made a bad assumption.

Sometimes you can’t find the right part and have to find an alternative. Sometimes things break and you have to find a work around. Sometimes you have to build something yourself. And sometimes, even specially made replacement parts like ours don’t fit.

Pot handle that won’t fit on one side

Take this example from a very nice Amazon customer that contacted us for some help. He ordered our single screw pot handles, and one side fit just fine, but on the other, the hole in the handle didn’t line up with the screw hole in the bracket.

He tried the working handle on that side and it also didn’t line up. It seems the bracket on the pot is different between the two sides. This leads me to speculate on a couple of things; whether our replacement handles are less flexible in situations like these than OEM Revere Ware ones, or perhaps these situations happened in the factory on occasion and they just accommodated a slightly different bracket by modifying a Bakelite handle to fit.

The latter is what I suggested to the customer that he try, and widening the hole in the Bakelite just a bit allowed him to get the screw in and all is well.

I decided to get out my Dremel tool to demonstrate some modifications for a situation like this. You can either widen the screw hole, as the customer did, or enlarge the area where the bracket fits, so the handle can slide down a bit.

The one one the left has had the screw hole widened upward using a round Dremel bit, but a round file will work just as well. The one on the right I ground down some of the bottom ledge of the recessed area where the metal bracket on the pot sits, so that the handle can slide up a bit, thus centering the hole in the Bakelite on the hole in the bracket. The nice thing about both of these modifications is that they are at the back of the handle, and won’t show, and / or will be hidden by the screw from the front.

As a reminder, whenever sanding, filing, or grinding Bakelite, like other materials that will generate a fine particulate dust, always wear a safety mask, preferably an N95 type. We’ve all got some of those around these days.

Knobs that won’t screw on

Another situation we’ve run into a few times recently is when our knobs won’t screw on customers Revere Ware lids. While we do see the rare defective nut insert that is missing threads entirely, this isn’t very common. I’ve tested our knobs on quite a few of my lids lately and haven’t yet found a knob or a lid that won’t work together. But I have found some that are a bit difficult to screw on. This can be caused by rust developing on the threads, making them slightly larger. Because water can often get under the Revere Ware lid knobs and that area doesn’t dry out easily, rust can develop. Yes, even stainless steel can rust given enough opportunity. Rust can also develop when you have dissimilar materials touching, like stainless steel (screw) and aluminum (nut insert) together.

To get past this, you can try “sanding” the rust off with some WD-40 and a green Scotch Brite pad. Sometimes screwing the knob on a little, then backing it off, and screwing it on some more, repeatedly, can get it on. One customer sent us the knob that didn’t work for him and it worked fine for me on all of my test lids. The point is that usually it isn’t the knob that is the problem.

In conclusion

One point of all this is to give some perspective. Things don’t always work the way they should but often a solution can be found if you just ask, or do a little web searching. We are always willing to help solve your problems, whether you buy from us or not.

Can, or have you, addressed the proper method for flattening curved bottoms?

Sadly, we have yet to find any method of repairing warping in the bottoms. Nothing we’ve tried seems to work and attempts at searching the web numerous times over the years has failed to find any solutions.